Understanding the Crucial Role of Cooling Tower Makeup Water Calculation

Related Articles: Understanding the Crucial Role of Cooling Tower Makeup Water Calculation

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to Understanding the Crucial Role of Cooling Tower Makeup Water Calculation. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Understanding the Crucial Role of Cooling Tower Makeup Water Calculation

.png)

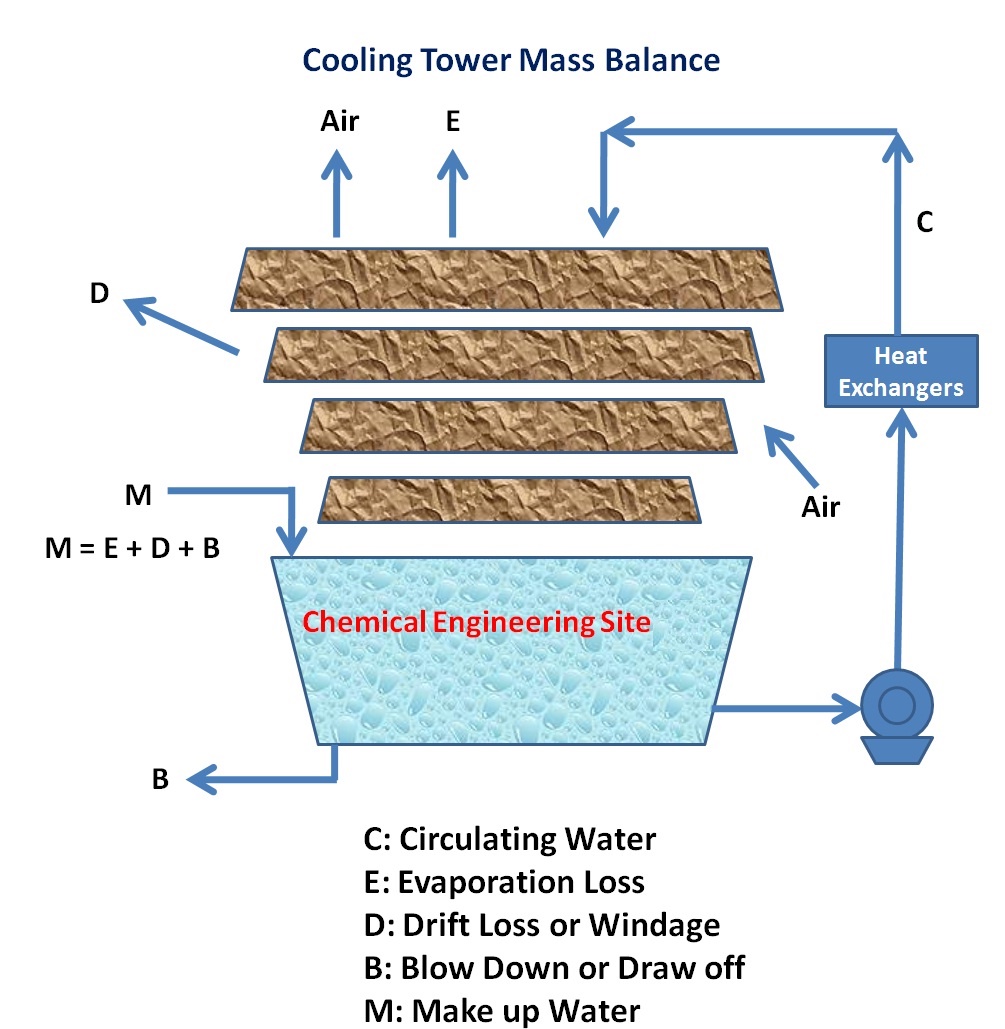

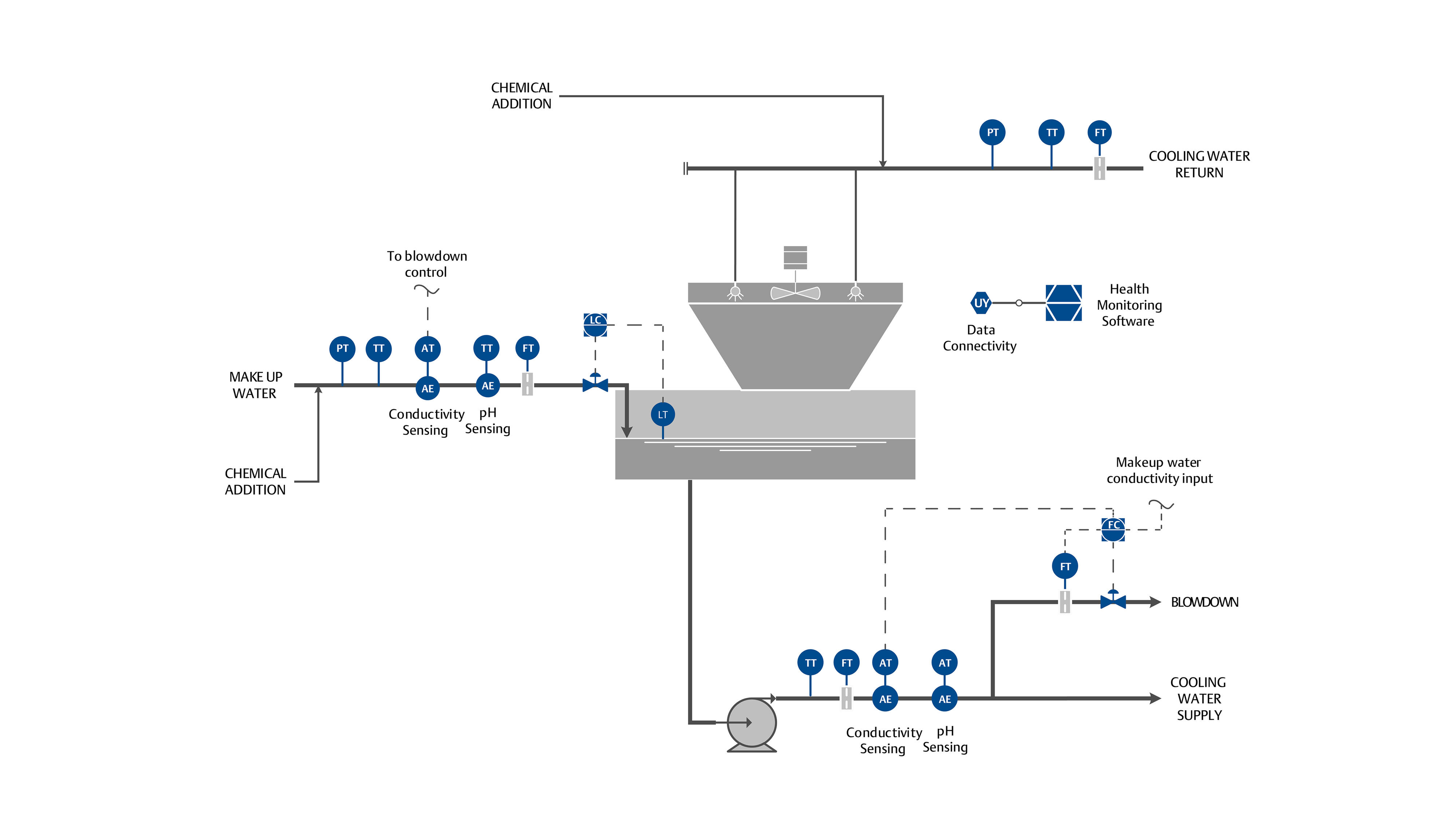

Cooling towers are essential components in various industrial and commercial applications, effectively removing excess heat from processes and systems. Their operation relies on a continuous water cycle, with a portion of the circulating water inevitably lost through evaporation and drift. This necessitates the replenishment of the water, known as makeup water, to maintain the cooling tower’s performance and efficiency. Accurately calculating the makeup water requirement is paramount for optimal cooling tower operation, ensuring cost-effectiveness and environmental sustainability.

The Importance of Precise Makeup Water Calculation

A well-calculated makeup water requirement ensures:

- Optimized Cooling Tower Performance: Maintaining the appropriate water level in the cooling tower is crucial for effective heat transfer. Insufficient makeup water can lead to reduced cooling capacity, impacting the overall process efficiency.

- Cost Reduction: Overestimating the makeup water requirement leads to unnecessary water consumption and increased operational costs. Conversely, underestimating it can cause system malfunctions and downtime, incurring even higher costs.

- Minimized Environmental Impact: Cooling towers utilize significant amounts of water. Precise makeup water calculations help optimize water usage, minimizing water consumption and reducing the environmental footprint.

- Improved Water Quality: Excessive makeup water can dilute the concentration of water treatment chemicals, potentially compromising water quality and increasing the risk of corrosion and scaling.

Factors Influencing Makeup Water Calculation

The makeup water requirement is influenced by various factors, including:

- Cooling Tower Design: The size, type, and design of the cooling tower directly influence the evaporation rate and, consequently, the makeup water requirement.

- Operating Conditions: Factors like ambient temperature, humidity, and wind speed significantly impact evaporation rates, affecting the makeup water calculation.

- Water Quality: The quality of the makeup water, including its hardness and mineral content, can impact the cooling tower’s efficiency and lifespan, necessitating adjustments to the makeup water calculation.

- System Load: The heat load imposed on the cooling tower, determined by the process requirements, influences the water evaporation rate and, subsequently, the makeup water requirement.

Methods for Calculating Makeup Water

Several methods are employed to calculate the makeup water requirement, ranging from simple estimations to sophisticated models:

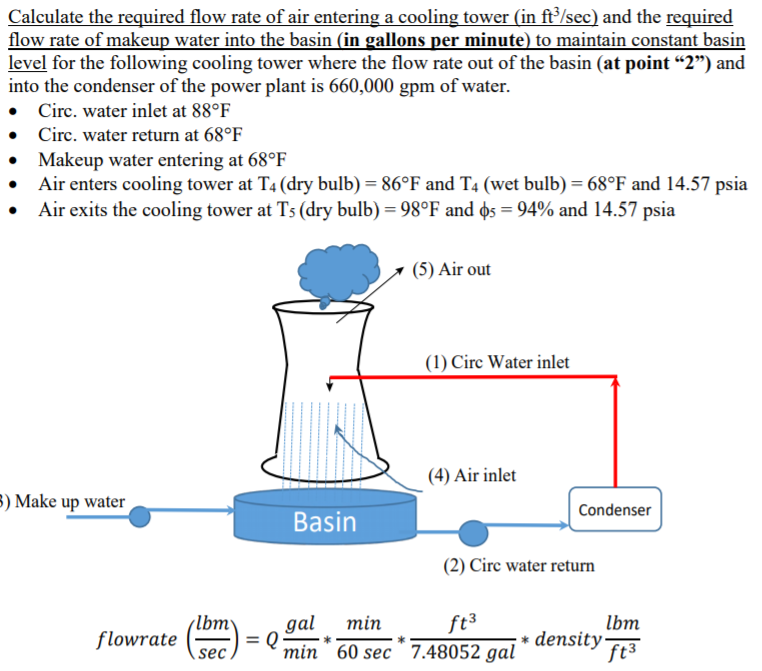

- Empirical Formulas: Simple formulas based on empirical observations provide a quick estimate of the makeup water requirement. These formulas typically consider factors like cooling tower size, operating temperature, and humidity.

- Evaporation Rate Calculation: More precise methods involve calculating the evaporation rate based on the cooling tower’s operating conditions and water properties. This approach uses psychrometric charts and equations to determine the water loss due to evaporation.

- Computer Simulation Models: Advanced software programs utilize complex algorithms and data inputs to simulate the cooling tower’s performance, providing accurate predictions of makeup water requirements under various operating conditions.

Utilizing Excel for Makeup Water Calculation

Microsoft Excel, a widely available spreadsheet software, offers a powerful tool for calculating makeup water requirements. Users can create spreadsheets that incorporate various factors influencing the calculation, including:

- Cooling Tower Design Parameters: Dimensions, type, and operational characteristics of the cooling tower.

- Operating Conditions: Ambient temperature, humidity, wind speed, and other environmental factors.

- Water Quality: Hardness, mineral content, and other relevant water properties.

- System Load: Heat load imposed on the cooling tower by the process.

By inputting these parameters into the spreadsheet, users can automatically calculate the makeup water requirement, providing a comprehensive understanding of the cooling tower’s water consumption.

Benefits of Using Excel for Makeup Water Calculation

- Flexibility and Customization: Excel allows users to customize the spreadsheet based on their specific cooling tower design and operating conditions, ensuring accuracy and relevance.

- Ease of Use: Excel’s intuitive interface and familiar functions make it easy to learn and use, even for users without extensive spreadsheet experience.

- Data Visualization and Analysis: Excel provides tools for creating charts and graphs, enabling users to visualize the makeup water requirement over time and identify trends.

- Cost-Effectiveness: Excel is readily available and does not require additional software purchases, making it a cost-effective solution for makeup water calculation.

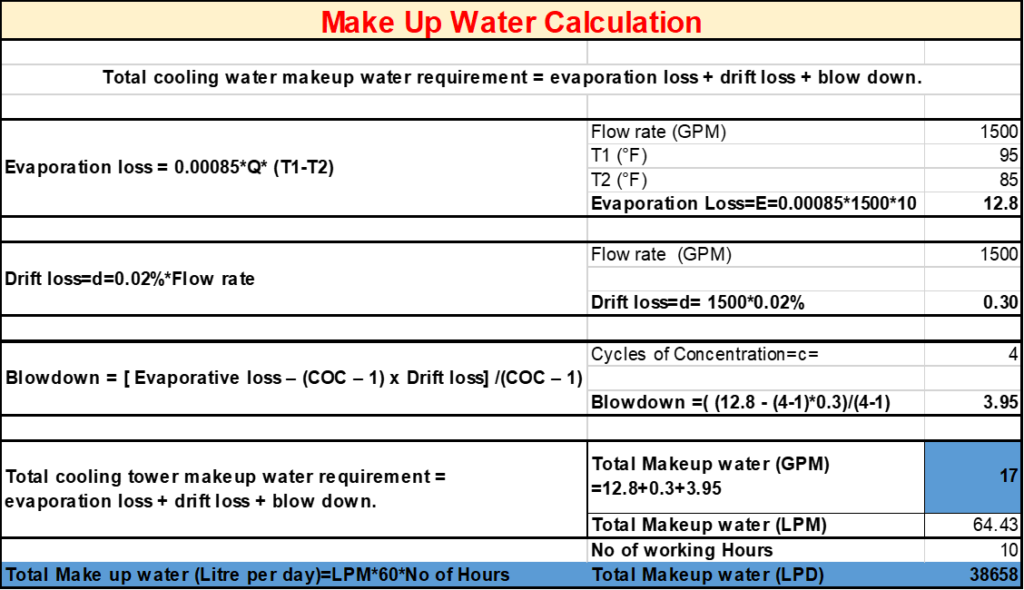

Example of a Makeup Water Calculation Spreadsheet in Excel

A typical Excel spreadsheet for calculating makeup water might include the following sections:

-

Input Parameters:

- Cooling tower size (m³)

- Water flow rate (m³/h)

- Ambient temperature (°C)

- Relative humidity (%)

- Wind speed (m/s)

- Water temperature (°C)

- Water hardness (ppm)

-

Calculations:

- Evaporation rate (m³/h)

- Drift loss (m³/h)

- Total water loss (m³/h)

- Makeup water requirement (m³/h)

-

Output:

- Total makeup water requirement (m³/day)

- Makeup water requirement per hour (m³/h)

- Water usage cost per day ($)

The spreadsheet can be further customized to include additional factors, such as water treatment chemical consumption, water quality adjustments, and cost analyses.

FAQs on Cooling Tower Makeup Water Calculation

Q: What is the typical makeup water requirement for a cooling tower?

A: The makeup water requirement varies significantly based on the cooling tower’s size, operating conditions, and water quality. However, a typical range for industrial cooling towers is between 5% and 15% of the circulating water flow rate.

Q: How often should I calculate the makeup water requirement?

A: It is recommended to recalculate the makeup water requirement at least annually, considering any changes in operating conditions, system load, or water quality.

Q: How can I reduce the makeup water requirement?

A: Several strategies can help minimize makeup water consumption:

- Optimize cooling tower operation: Maintaining optimal water flow rate, minimizing drift loss, and ensuring proper water treatment can significantly reduce evaporation rates.

- Utilize water conservation technologies: Implementing water-saving measures like closed-loop cooling systems or utilizing recycled water can reduce the overall water consumption.

- Upgrade cooling tower technology: Newer cooling tower designs often incorporate features that minimize evaporation and drift losses, leading to reduced makeup water requirements.

Q: What are the consequences of inaccurate makeup water calculation?

A: Overestimating the makeup water requirement leads to unnecessary water consumption and increased operational costs. Conversely, underestimating it can cause system malfunctions and downtime, potentially leading to production disruptions and even more significant financial losses.

Tips for Effective Makeup Water Calculation

- Use accurate data: Ensure all input parameters used in the calculation are accurate and up-to-date.

- Consider all relevant factors: Include all factors influencing the makeup water requirement, such as cooling tower design, operating conditions, water quality, and system load.

- Regularly monitor and adjust: Monitor the actual water consumption and adjust the makeup water calculation accordingly to ensure optimal performance.

- Utilize professional expertise: Consult with cooling tower experts or engineers to ensure accurate and reliable makeup water calculation.

Conclusion

Accurately calculating the makeup water requirement is essential for optimizing cooling tower performance, minimizing operational costs, and reducing environmental impact. By utilizing Excel spreadsheets or specialized software, users can effectively calculate the makeup water requirement, ensuring efficient cooling tower operation and responsible water management. Regular monitoring, adjustments, and professional expertise are crucial for maintaining accurate calculations and maximizing the benefits of optimized makeup water management.

Closure

Thus, we hope this article has provided valuable insights into Understanding the Crucial Role of Cooling Tower Makeup Water Calculation. We hope you find this article informative and beneficial. See you in our next article!